Mechanical Seals or Compression Packing

Flat gasket dimensional table for flanges according to Standard EN 1514-1

2023年6月27日

Disc Spring DIN2093

2023年6月29日Sealing Rotating Shafts Mechanical Seals or Compression Packing?

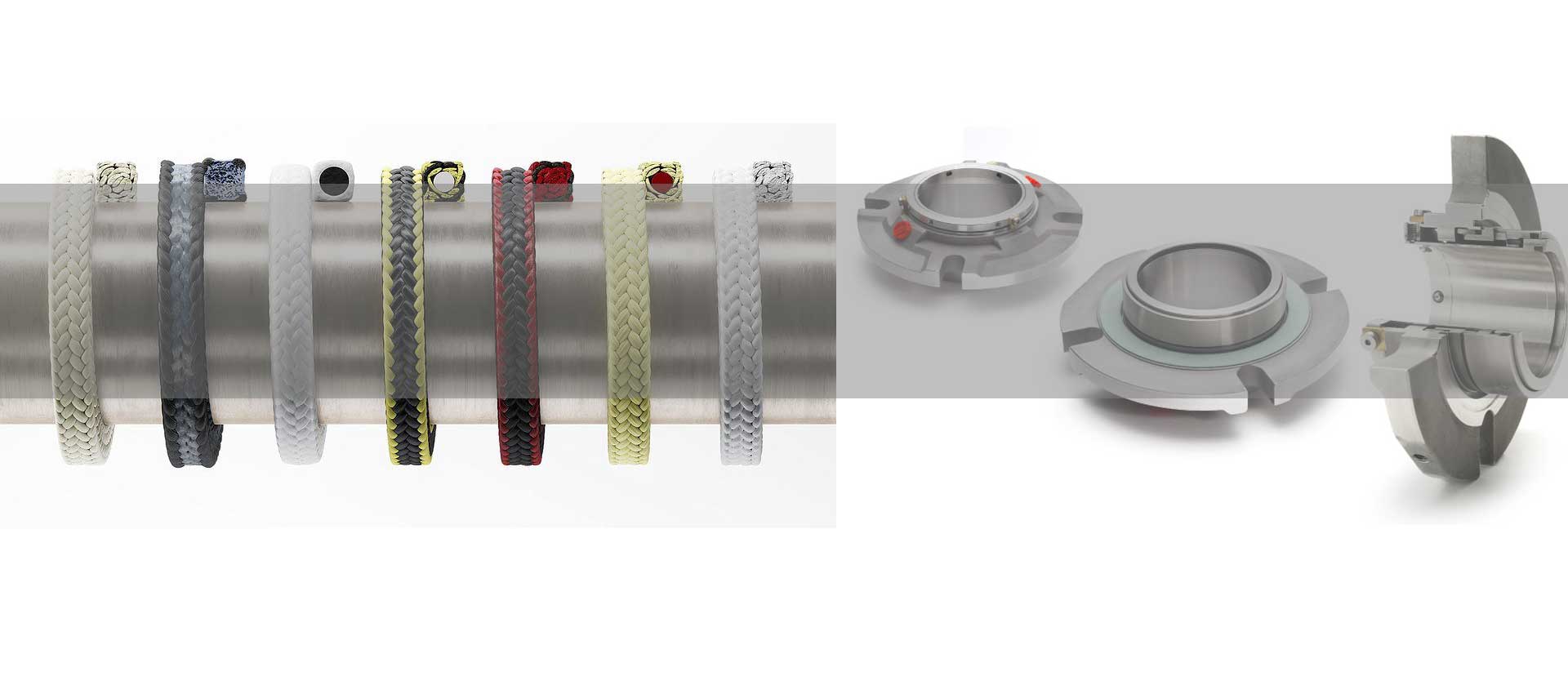

Sealing rotating shafts are most often accomplished by selecting one of two methods; Mechanical Seal or Compression Packing. Selection is determined by reviewing the applications technical, environmental, and commercial considerations. Both sealing methods have strengths and weaknesses depending on the application and objectives of the process owner. The summary below is intended as a general overview only as each subject touched can be covered in much greater detail. The reader should consult industry experts on mechanical seals and/or compression packings if specific detailed information is required. Most often mechanical seals are selected when it is critical to have as close to zero leakage as possible. Examples include but are not limited too; Toxic chemicals, flammable liquids, hazardous substances and other applications where it is critical to eliminate gland leakage. Compression Packings on the other hand are selected when the above is not present and operational reliability, simplicity of installation and maintenance is critical. These include services where mechanical seals frequently have problems such as liquids with solids present (such as Mining processes, Pulp & Paper, Waste Water, Power Generation & Metals processing as a few examples). The reasons for this will be evident with the strengths and weaknesses of each technology listed below.

Weaknesses of Mechanical Seals

- Requires “clean” flush fluid to lubricate seal faces does not tolerate process fluids with solids present as well as compression packing

- Sensitive to shaft deflection, axial movement & vibration caused by cavitation, process upsets and/or old worn equipment

- Sensitive to flush water pressure fluctuations, sudden drop in flush pressure can cause seal to fail.

- Require tight tolerances of seal faces, surface finish and tolerance of shaft/sleeve (+0 to – .002 inch and <= 32 rms)

- Except for split mechanical seals, the equipment must be disassembled for installation

Weaknesses of Compression Packings

- Some leakage at gland is needed for proper lubrication of packing shaft/sleeve interface removes heat and lubricates

- Wear to shaft/sleeve occurs due to friction

- Requires periodic adjustments to maintain load and lower leakage rate

- Limitations on shaft speed and operating pressures

- Dependent on user technical skills for installation and maintenance

In summary neither Mechanical Seals or Compression Packings are the best option for all services. Each have a place in the Industry depending on specific needs of the respective operating companies and processes. Further when both can meet the technical criteria the selection is often determined by economic, environmental and/or operating companies experience and preferences.