PTFE Lantern Ring

Introduction of Engineering Plastics

2023年6月13日PTFE Lantern rings

Also well know by Universal Seal Cage are usually in the center of every compression packing set in a centrifugal pump. They are simple components, but get something wrong when selecting, installing or operating them, and big problems may occur in the stuffing box. A lantern ring is placed between packing rings in each packing set and extends the life of the packing, stuffing box and shaft. Ultimately, lantern rings increase the life span of the pump system.About Lantern Ring

Ensuring stuffing box reliability and controlling the environment mitigate many issues in the ‘space’ where it happens.

PTFE Lantern rings serve three purposes: protection, cooling and lubrication. They protect the stuffing box and the installed packing by providing an access point for flush water. If process fluids or other contaminants enter the stuffing box and are not removed by flush water, several problems occur, including:

• damaged or destroyed packing

• shaft or sleeve damage

• stuffing box wear

A lantern ring also gives the stuffing box an outlet to assist with cooling. It allows the system to avoid being completely closed off and assists in mitigating overheating. The final lantern ring purpose is lubrication. Compression packing causes friction along the shaft and stuffing box walls or casing.

Fluid entering through the lantern ring lubricates the packing. The liquid reduces friction, limits the wear of the machine’s parts and decreases heat within the system.

Materials for Lantern Rings

Selecting the correct material for the application is critical. Lantern ring selection should be given equal consideration because they are equally as important as packing. PTFE and PEEK, general material for Lantern Ring.PTFE & PEEK Strengths & Weaknesses

| PTFE Strengths | PTFE Weaknesses |

|---|---|

| Broad chemical resistance | Creep and cold flow |

| Nonflammable | Relatively soft |

| Low-temperature flexibility | Low thermal dissipation |

| Low coefficient of friction | Poor dimensional stability |

| High-temperature stability | High material shrinkage |

| Easy to process | Low rigidity |

| High-frequency resistance | Low electrical conductivity |

| PEEK Strengths | PEEK Weaknesses |

|---|---|

| Tensile strength, elongation and wear properties | Not suitable for applications involving nitric or sulfuric acid |

| Chemical resistance | More costly |

| Withstands long exposure to high pressure, water and steam | Difficult to process |

| Low flammability | |

| Resistant to gamma radiation | |

| Continuous use up to 500F |

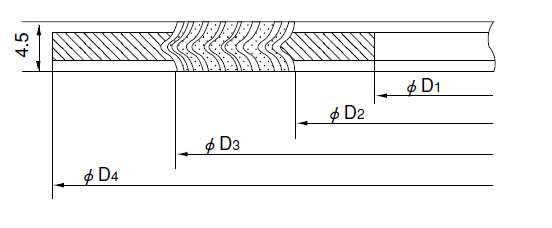

Size of Lantern Ring

LENGTH 1200MM| 7,6x11,4 | 9,0x 13,2 | 9,0x19 | 9,4x13,2 | 10,5x 14,3 |

| 10,5x22 | 11,1x15,6 | 12,1x17 | 12,1x25,4 | 12,6x17 |

| 13,5x19,2 | 14,2x19,2 | 15,2x20,6 | 15,2x31 | 17x22,1 |

| 18,1x22,1 | 18,1x38 | 19 x23,8 | 20,8x25,2 | 23,5x28,2 |

| 1/4" x 5/16" x 48" | 1/4" x 3/8" x 48" | 1/4" x 1/2" x 48" | 5/16" x 7/16" x 48" | 5/16" x 5/8" x 48" | 3/8" x 1/2" x 48" | 3/8" x 3/4" x 48" |

| 7/16" x 9/16" x 48" | 7/16" x 7/8" x 48" | 1/2" x 5/8" x 48" | 1/2" x 1" x 48" | 9/16" x 11/16" x 48" | 9/16" x 1" x 48" | 5/8" x 3/4" x 48" |

| 5/8" x 1" x 48" | 3/4" x 7/8" x 48" | 3/4" x 1" x 48" | 7/8" x 1" x 48" | 1" x 1" x 48" | 7/16" x 5/8" x 48" | 1/2" x 11/16" x 48" |