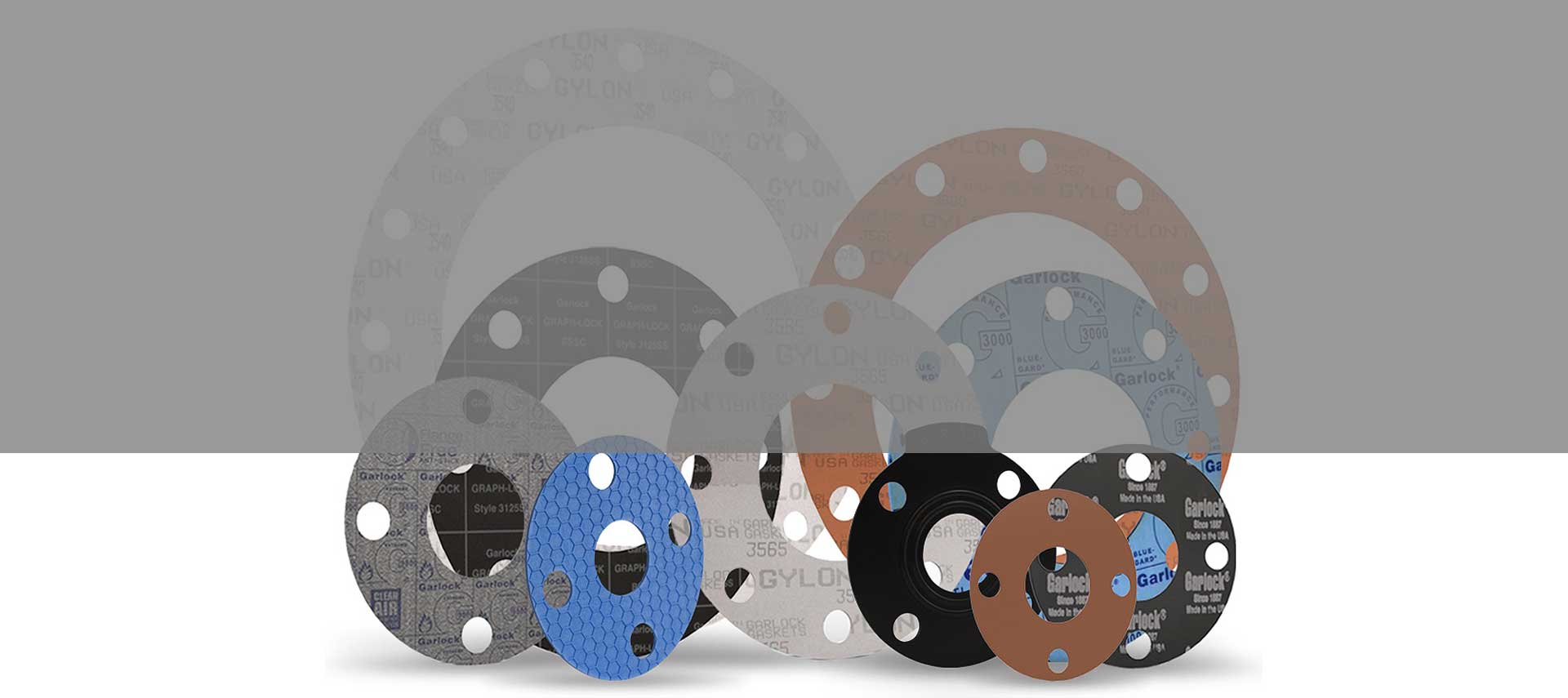

Gaskets Material

Flat gasket dimensional tables for flanges according to Standard ASME B16.21 (ANSI B16.5)

2023年6月30日The Domestic Urea Price Fell 6.04% in June

2023年7月7日Graphite Gasket Material

A gasket for high temperature and wide chemical applications, it is extreme stability material, reinforced by SS304/SS316 stainless steel foil insert (or tanged foil) . lt is a universal sheet gasket, excellent thermal stability, chemical resistance and negligible creep characteristics.

Material: Flexible Graphite Sheet

Metal Layer: SS304/SS316 flat foil/ SS304/SS316 tanged foil/Tanged tinplate foil

Thickness(mm): 0.8; 1.6; 2.0; 3.2; 4.0; 5.0;

Wideth * Length(mm) : 1000*1000; 1500*1500

Article from https://www.sungran.cn/products/gasekt-sheet/

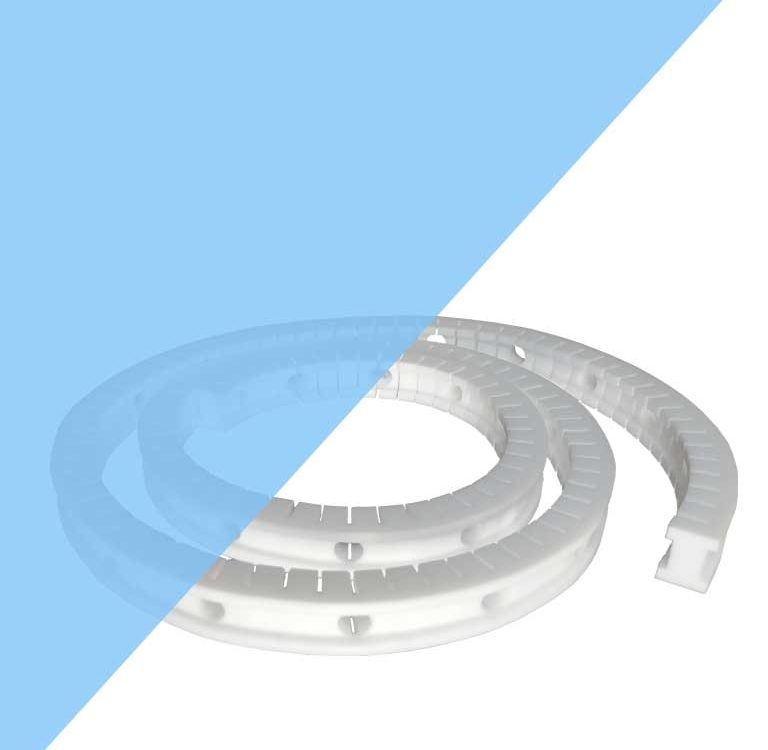

PTFE Series Gasket Material

PTFE Series is the most widely used plastic for industrial sealing.

The only media that can chemically attack PTFE are liquid alkaline metals and free fluorine. PTFE has excellent properties for electrical insulation, anti-stick, impact resistance and an extremely low coefficient of friction.

In order to improve PTFE character for different sealing condition, there are following normal ptfe sealing material:

Expanded PTFE, Modifying PTFE, Filled PTEF.

Kinds of PTFE material can be machined lots of elements, by CNC Milling/ Turning/ Routing/ Cutting/ Fabrication.

Article from https://www.sungran.cn/products/gasekt-sheet/

Asbestos Free Material

Asbestos-free gasket is according to the requirements of various specific working conditions, with asbestos-free sealing materials (using aramid fiber, high temperature resistant synthetic mineral fiber, oil resistant rubber and other materials), with rolling method or a variety of tools stamping, shear of various shapes of sealing products.

According material feature, it has different material formula. Such as ori-resistant, acid-resistant, press grade, temperature grade(from 100℃ to 800℃). So we can control cost according usage and material working condition.

Choosing right material, not only material long serve life, but also saving cost.

Article from https://www.sungran.cn/products/gasekt-sheet/